TYPES OF PRINTING ON FABRICS - WHICH ONE TO CHOOSE?

In today's dynamic world, where individualization has become a key element of self-expression, fabric printing plays a vital role in shaping a unique style and message. From personalized clothing to corporate gadgets, the variety of fabric printing technologies offers endless possibilities for creating unique designs and patterns. In this article, we'll take a look at the fascinating world of different types of fabric printing, examining popular methods, their advantages and applications.

The most popular types of printing

Below you will find a discussion of the different types of printing, along with their most important features and applications.

Screen printing

Screen printing is a classic type of printing that uses a screen to transfer ink onto fabrics. The process is based on the principle of passing ink through holes in the screen, creating a pattern. In its preparation, the screens are molded with the chosen pattern, and then the ink is pushed through the screen onto the fabric using a squeegee.

This method is distinguished by its durability, and is ideal for sportswear, advertising gadgets and promotional products. Advantages also include high quality and the availability of different types of inks. Nevertheless, screen printing can face limitations in the number of colors, and costs for small runs are relatively higher than in other types of fabric printing.

DTG digital printing

DTG printing, or direct to fabric printing, is an innovative printing technique that is significantly impacting the printing industry. The process enables ink to be precisely applied to fabrics using a special digital printer. Advantages of this technology include beautiful colors, precision detail and low costs when producing small runs.

DTG digital printing is used in the creation of personalized garments, personalized T-shirts and is flexible in terms of the type of fabric. Still, there can be challenges with large print runs due to cost and the need for a specialized printer. This modern technology is gaining popularity among designers and manufacturers, offering individuality and high quality printing.

Sublimation

Sublimation is an innovative printing method that uses a unique process of going directly from solid to gas, bypassing the liquid phase. The ink, in the form of a liquid coloring substance, turns into a gas under the influence of heat, penetrating the structure of the fabric fibers. Sublimation's popularity in the sports industry is due to its durability, abrasion resistance and full color capability, which is important for intense physical activities.

It is also characterized by high quality details, lack of a perceptible layer and resistance to fading. Sublimation is versatile, being suitable for a variety of fabrics, which expands the possibilities for designers. It is widely used in the production of sports apparel and gadgets, offering durable and aesthetically pleasing prints. These types of printing open up new perspectives for designers, making it possible to create dynamic and innovative products with exceptional print quality.

Flex/flock film

Flex and Flock film are versatile materials for printing on fabrics, offering different effects depending on the needs of the project. Flex is a flexible polyurethane film with a smooth surface, ideal for fine prints with sharper details. Flock film, on the other hand, contains fibers, giving a soft velvet-like effect, perfect for three-dimensional designs.

Both films feature flexibility, making them ideal for a variety of fabrics, including sportswear, maintaining durability and abrasion resistance. They are ideal for printing on sportswear, logos on polo shirts or personalizing gadgets. Despite some color limitations compared to other types of textile printing, the films offer great durability and aesthetics. Cutting out the design with a plotter is the only necessity, which can be time-consuming, especially for complex designs.

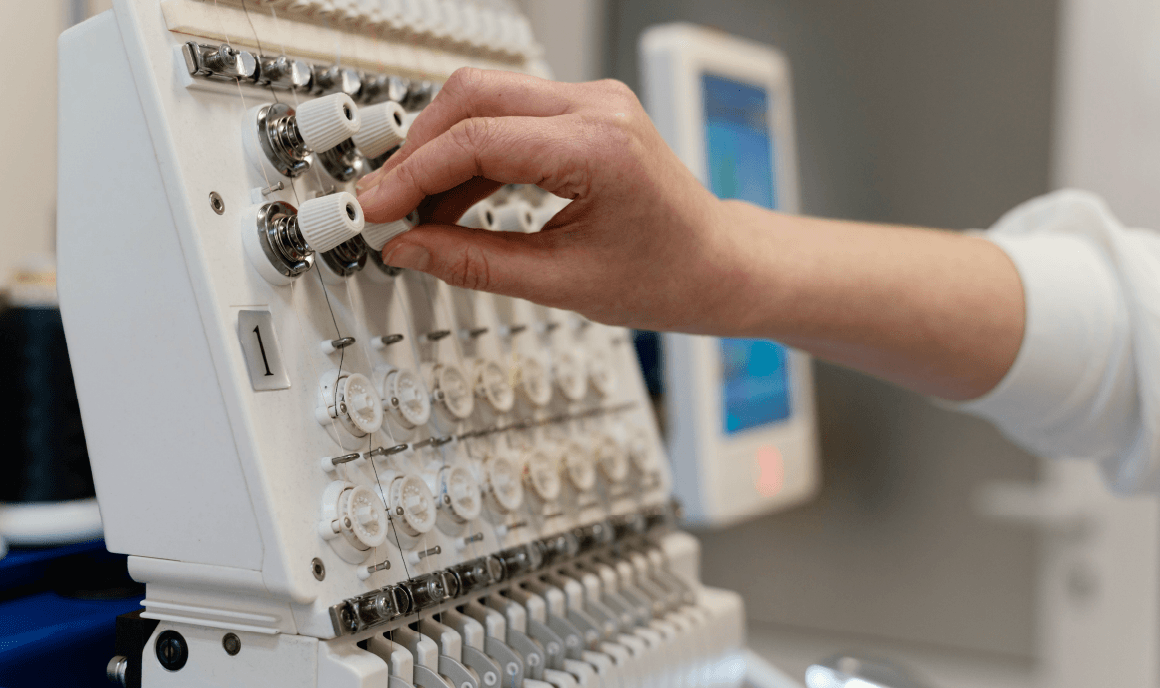

Computer Embroidery

Computer Embroidery is a sophisticated type of printing, combining elegance, precision and durability.

The process begins with the creation of a design on a computer, which is then programmed into an embroidery machine. The needle stitches the fabric according to the pattern, giving a three-dimensional effect and precise details.

Computer embroidery is distinguished by its elegance and durability of prints, ideal for everyday clothing. It provides high quality detail, making it perfect for projects that require subtlety. Suitable for a variety of fabrics, both natural and man-made, although the flexibility of some materials may affect the results. Used for personalizing business apparel, printing on towels or premium accessories. Although it can be more time-consuming than other types of fabric printing, computer embroidery offers a unique effect, especially in the context of producing premium products.

Thermal transfer

This is an innovative type of printing, where the design is transferred from thermal transfer paper to fabric using high heat and pressure. The process involves printing the design on the thermal transfer paper using a printer, and then transferring it to the fabric by using a hot press or iron.

It is a popular method, especially for producing shirts with small print runs, where production costs play an important role. In addition, thermal transfer has found its way into DIY projects, allowing easy personalization of clothes, bags or pillows at home. Unfortunately, prints of this type can be less durable than some other methods, especially with frequent washing. There is also the possibility that the print will take on a "plastic" look and feel more tactile. In addition, not all types of fabric are suitable for thermal transfer, which can affect different results depending on the material.

Which printing technology to choose?

Choosing the right method from such a wide variety of textile printing is a key step in the production process. The decision itself should be based on consideration of several important factors. Durability, quality, production costs and availability are key elements to consider when choosing a printing method. It is also worth taking into account the specifics of the project, the type of fabric, and expectations regarding the details and aesthetics of the print. The final decision should be an informed one, tailored to the individual needs and conditions of the project in question, which will ensure that the best visual and functional results are achieved.

During the production of our products, we use many forms of printing, depending on what the customer needs. In our offer we have such products as cotton bags with printing, cotton bags without printing, advertising backpacks, cotton pouch with advertising printing.

Summary

The variety of textile printing methods offers designers and manufacturers a wide range of options to suit different needs and expectations. Each printing technique, from traditional screen printing to innovative digital printing, has its own unique advantages and limitations. The final choice of printing type should be tailored to the specific needs of the project, taking into account the balance between aesthetics and functionality.

MART’S BAGS

+48 787 340 123